In semiconductor manufacturing, you might have come across the term “STI” or Shallow Trench Isolation. I want to share some thoughts on what STI is and why we need it in modern chips. We often use STI to isolate devices on a chip more efficiently and compactly than older methods. But what exactly is it, and how does it work? Let’s explore!

Understanding STI

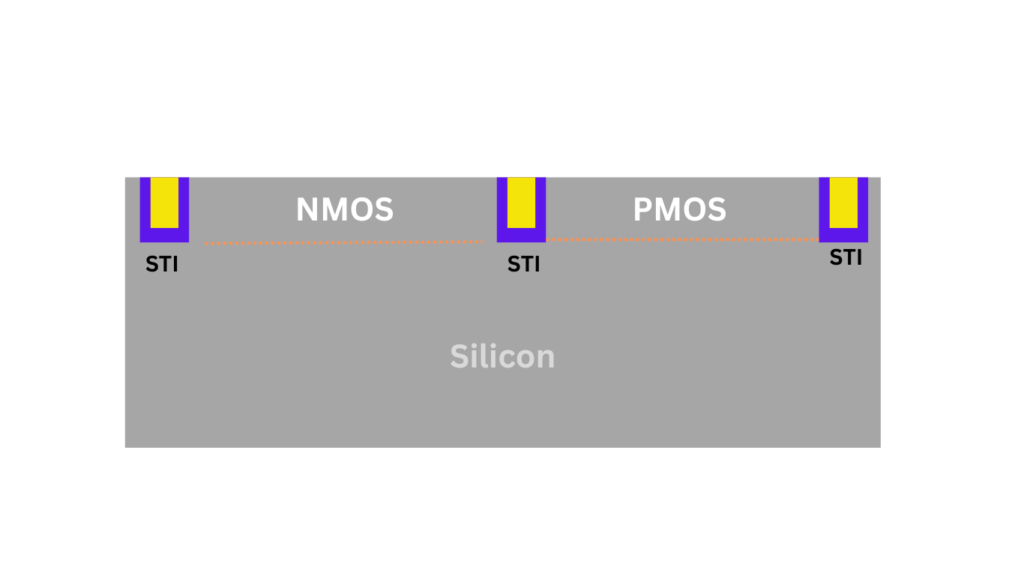

STI stands for Shallow Trench Isolation. In simple terms, it’s a technique where we etch shallow trenches into the silicon wafer and fill them with an insulating material, usually an oxide. When you do this, you create barriers between different devices on the chip, like transistors, without using much space. This is important because, as chip designs get smaller and more packed with components, we need effective ways to prevent electrical interference between these components.

When we design integrated circuits, one of the key steps we take to prevent unwanted electrical interaction between transistors is using Shallow Trench Isolation (STI). In this process, we etch narrow trenches into the silicon substrate and then fill them with a dielectric material, usually silicon dioxide (SiO₂).

This insulating layer helps us keep the active regions of transistors properly separated, so they function independently without interference. If you’re working on CMOS technology, you’ll often rely on STI to ensure device isolation and signal clarity across the chip.

Why Do We Need STI?

I think STI became essential as semiconductor devices became more miniaturized. In the past, we used methods like reverse-biased p-n junctions for isolation, but those took up a lot of space and limited how close we could place devices. With STI, you can have very narrow trenches, which means you can pack devices closer together. This makes chips smaller, faster, and more energy-efficient.

From what I understand, using STI also improves the electrical performance of the chip. Unlike older methods, it doesn’t significantly affect how the devices behave electrically, which is crucial for modern, high-performance circuits. You can achieve better isolation with less impact on the device’s operation.

How Does STI Work?

When we use STI, the process involves etching trenches into the silicon surface using a method called reactive ion etching. These trenches can be a few hundred nanometers deep or even more, depending on the specific needs of the chip. After etching, the trenches are filled with an oxide layer, either by thermal oxidation or by deposition. We then use a technique called chemical-mechanical polishing (CMP) to flatten the surface and remove any excess material.

By filling these trenches with insulating material, we create a barrier that prevents electrical signals from leaking between neighboring devices. You might see this used a lot in CMOS logic chips and other semiconductor devices where space is a premium and performance is key.

Conclusion

In summary, STI, or Shallow Trench Isolation, is a critical technique in semiconductor manufacturing that allows us to create more compact, efficient, and high-performance chips. By using narrow trenches filled with oxide, we can isolate devices effectively without sacrificing space or electrical performance. Whether you’re a semiconductor professional or just someone interested in technology, understanding STI gives you a glimpse into the complexity and innovation behind the chips that power our world today.