When we talk about using copper in chip manufacturing, we must consider some specific challenges. As you might know, copper has become the go-to material for interconnects in recent years due to its excellent conductivity. However, I want to share with you the main problem that comes with using copper: electromigration (EM).

Electromigration is like a slow movement or “drift” of metal atoms caused by the flow of electrical current. When we use copper, EM can become a significant issue because copper atoms tend to migrate, especially at the surface, due to the low activation energy needed for surface diffusion. This can lead to voids forming in the copper wires, which can eventually cause circuit failures.

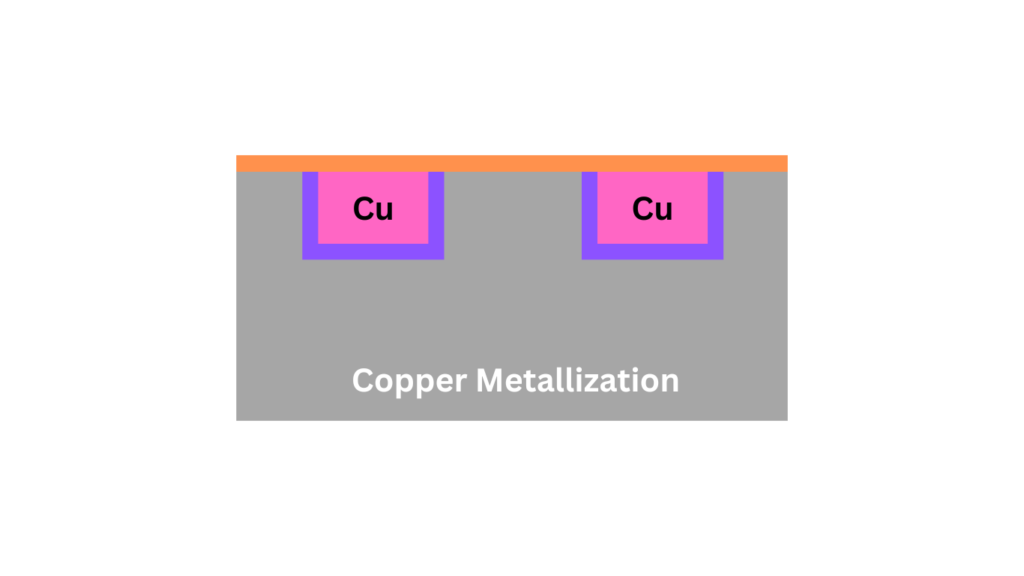

One of the technologies we rely on to fabricate copper interconnects is called Damascene technology. Imagine it like this: first, we carve out trenches or holes in a dielectric material, then we fill them with copper, and finally, we polish the surface to remove any excess copper. This is a simplified explanation, but it gives you an idea. There’s also something called Dual-Damascene technology that allows us to deposit copper for both interconnect and via layers in a single step, reducing some of the manufacturing steps.

Now, you might think, “Why don’t we just keep using this process if it’s efficient?” The catch is that copper has a tendency to diffuse into neighbouring silicon and silicon oxide at high temperatures. This diffusion can create a layer of copper silicide, which has poor conductivity and can mess up the semiconductor properties of silicon. So, to prevent this, we need to add barrier layers between the copper and the dielectric materials.

We generally use two types of barriers: a metal liner that prevents copper diffusion within the trench, and a dielectric cap that sits on top of the interconnects. These barriers help to keep copper where it should be and ensure that everything functions smoothly. But it’s not all smooth sailing. We need to choose these barrier materials carefully to ensure they stick well to copper, can withstand high temperatures, and are mechanically stable even in thin layers.

Read also: Why are metallic interconnections commonly used?

What’s interesting is that when we change the diffusion barriers, we change the dominant mode of electromigration. If we block one diffusion path, like surface diffusion, another path, like grain-boundary diffusion, might become the main issue. And if we block grain-boundary diffusion, bulk diffusion could take over. It’s a bit like a game of whack-a-mole, where fixing one problem can lead to another.

How Can We Mitigate Them?

In summary, while copper is excellent for conductivity in chip interconnects, it brings challenges like electromigration and diffusion. To mitigate these, we use technologies like Damascene processes and carefully designed barrier layers. As we keep improving these methods, we can better control these issues and build more reliable and efficient chips.